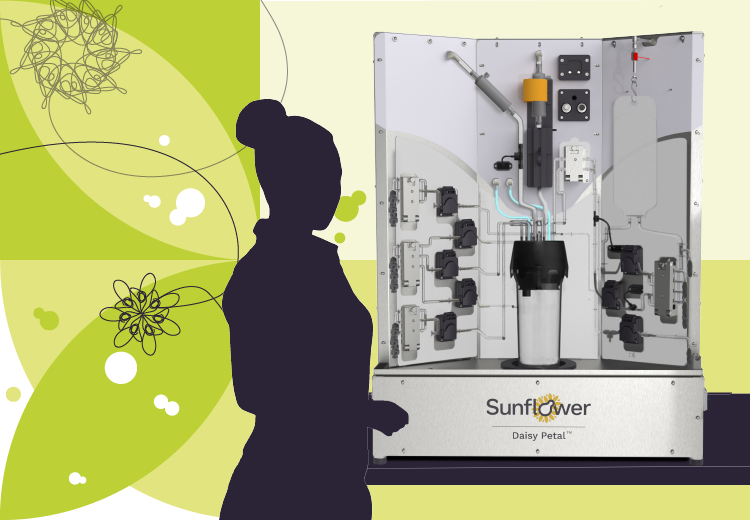

Daisy Petal™

Perfusion Bioreactor System

Straightforward fermentation,

no experience required.

Meet the Daisy Petal™

The first microbial perfusion fermentation system designed and built for continuous protein production, allowing you to make more protein with less space, effort, and cost.

Daisy Petal™ is the first fermentation system designed and built for continuous protein production by fermentation experts.

This breakthrough capability means it can produce as much protein as a bigger reactor for a fraction of the size and cost.

Additionally, the system is designed for accessibility. Sunflower’s intuitive single-use assemblies include a perfusion-enabled bioreactor with all necessary sensors, filters, connections, and tubing attached to a rigid panel. Every component is mounted where it needs to be, empowering non-expert users to intuitively install the single-use tubing assembly on the Daisy Petal™. Operations are fully automated by HelianthOS™, Sunflower’s universal operating system.

The Daisy Petal™ allows users to test key process parameters more efficiently, collect more data in one campaign, or simply produce greater quantities of cells or proteins.

The Daisy Petal™ is our pioneering benchtop automated single-use bioreactor system for continuous protein, molecule or cell line production using microbes. Daisy Petal™ is designed to help you achieve your R&D goals in drug/vaccine development, food technologies, synthetic biology or diagnostics development, without being a bioprocessing expert. ‘Plug-N’-Produce’™ features include a structured single-use bioreactor assembly for successful installation every time, comprehensive “hands-free” system automation by HelianthOS™ and a simple cloud-based application, Nursery™, for building your recipe and monitoring its progress during operation on the Daisy Petal™ .

- Works continuously for you: Daisy Petal™ uses our patented in-vessel cell retention device and operates perfusion or chemostat fermentations

- Maximize yields, minimize footprint: The 1 L working volume of Daisy Petal™ can deliver up to 20L of output process fluids in one operation

- Set up fast and properly: Intuitive layout and structured consumables mean no more installing tubing backwards (yeah, we’ve been there too)

- Process monitoring is standard: Daisy Petal™ systems and single-use assemblies come with ready-to-use sensors for pH, dissolved oxygen, temperature, and offgas monitoring

- Automated from start to finish: Sunflower’s universal HelianthOS™ software handles all the process controls and makes smart responses to deviations during a run. Remote and comprehensive process monitoring means you can walk away during Daisy Petal™ operations (it’s OK…go have lunch)

- Easy to program: Sunflower’s cloud based Nursery™ application lets you create recipes for the fermentation you want, from routine production to an efficient Design of Experiments (DoE)

- It’s all in the box: Daisy Petal™ comes with all the hardware and software you need right in the box to get started immediately (that’s right—no extra parts to source or install before you get going.)

- Continuously produce secreted proteins or small molecules from cells

- Cultivate lots of yeast, fungi, bacteria or other microorganisms

- Test out key parameters to optimize your fermentation (DoE studies)

- Evaluate new microbial cell lines

- Create batches of alternative protein for food product development

- Prepare new reagents for research and diagnostic development

- Advance your discovery and preclinical testing ideas